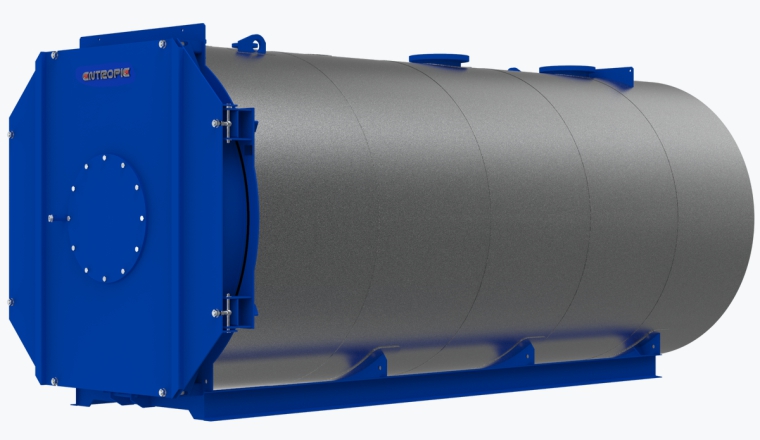

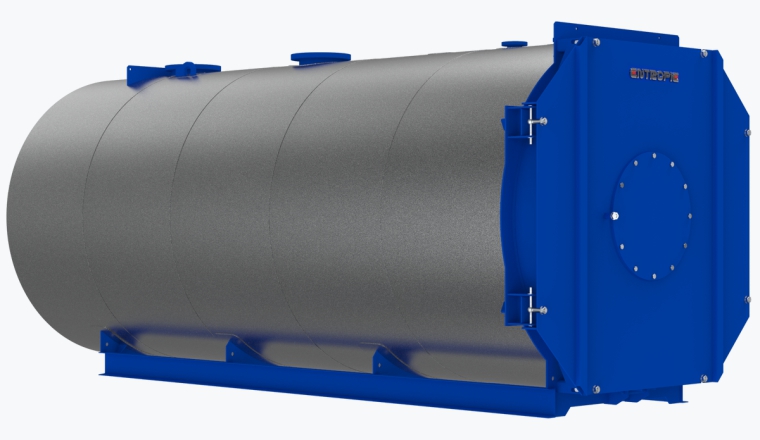

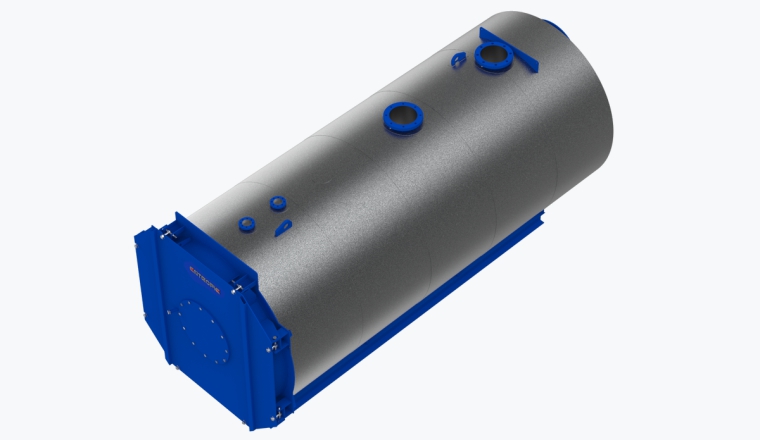

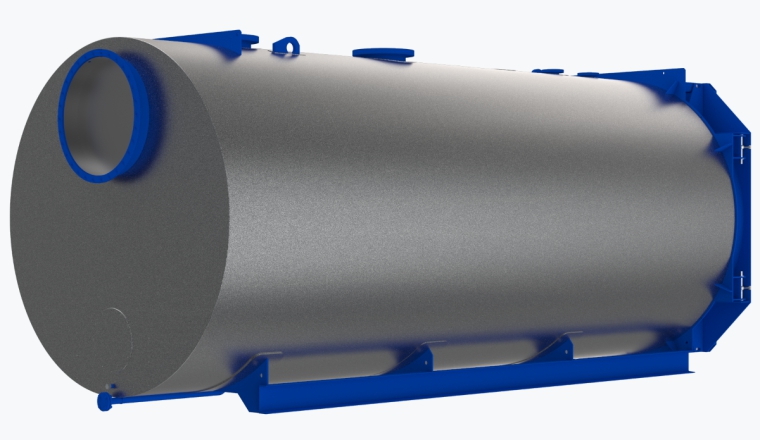

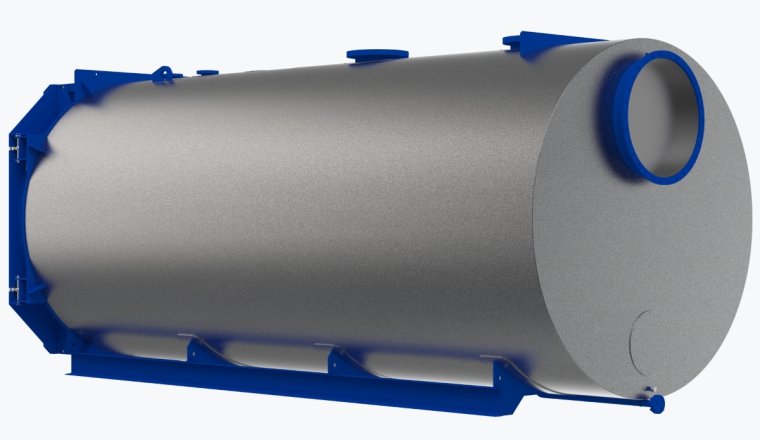

HOT WATER BOILER ТТ115

ENTROPIE boiler TT115 is a three-pass flame tube/smoke tube industrial hot water boiler made of steel. The boiler can be manufactured in the power range from 1 MW to 20 MW. The boiler is designed to produce hot water for heat supply of buildings and facilities, to support various purpose production processes.

- < 20 000 kW

- 10 bar

- 110 °C

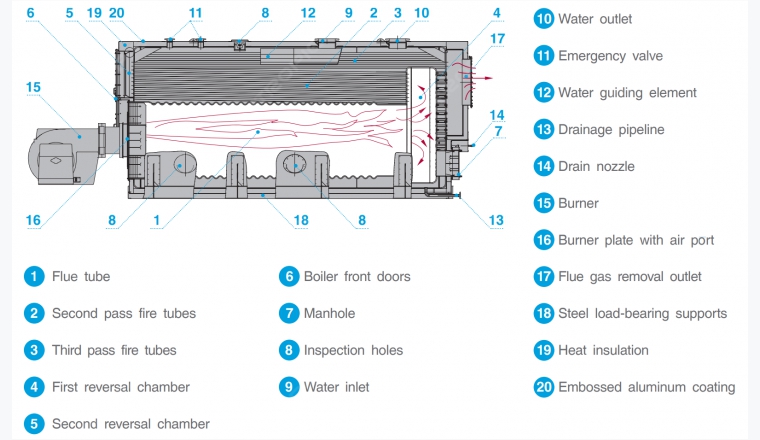

- Combustion chamber, fire tube, and boiler shell have a cylindrical shape. Convective heating surfaces are formed by second and third pass smoke tubes, located axisymmetrically around the combustion chamber. The two-three-row arrangement of the second pass smoke tubes provides a high heat transfer rate, increasing the boiler efficiency.

- The fully washed first reversing chamber is formed by the rear tube wall and the torispherical head. The second reversing chamber is formed by the front tube wall and the recess in the lining of the front door of the boiler, made in a special design to match any type of burner. The boiler front door with the burner installed can be fully opened in any direction.

- When the front door is opened an easy access to the combustion chamber and smoke tubes is provided for maintenance and cleaning of the boiler. Inspection and cleaning of the first reversing chamber are carried out through the combustion chamber. Water inlet and outlet pipes, as well as emergency line pipes are located on the top of the boiler. ENTROPIE boiler ТТ115 have two emergency line pipes. A water-guiding element is installed under the water inlet pipe, ensuring the most efficient distribution of the coolant inside the boiler.

- Three-pass flame tube/smoke tube design with low heat density of the combustion chamber ensures easy set-up of the boiler combustion modes and minimizes the harmful combustion products emission. Low aerodynamic resistance of the boiler ensures optimal selection of the burner.

- Installation of the first reversing chamber of the boiler on the same supporting-sliding (or rigid for boilers above 8.0 MW) anchor of the boiler furnace structure ensures compensation for cyclic thermal stresses and, thus, a long service life of the boilers.

Similar products

Production of high-quality boilers and equipment for obtaining heat energy in the form of hot water and steam.

-

HOT WATER BOILER ТТ50

- < 2 000 kW

- 6 bar

- 110 °C

-

HOT WATER BOILER ТТ100

- < 20 000 kW

- 6 bar

- 110 °C

-

HOT WATER BOILER ТТ100-01

- < 20 000 kW

- 8.5 bar

- 140 °C

-

Hot water boiler TT100 for greenhouses

- 12 100 kW

- 6 bar

- 115 °C

-

HOT WATER BOILER ТТ100-2

- < 20 000 kW

- 16 bar

- 170 °C

-

HOT WATER BOILER ТТ150

- < 20 000 kW

- 10 bar

- 150 °C